Introduction

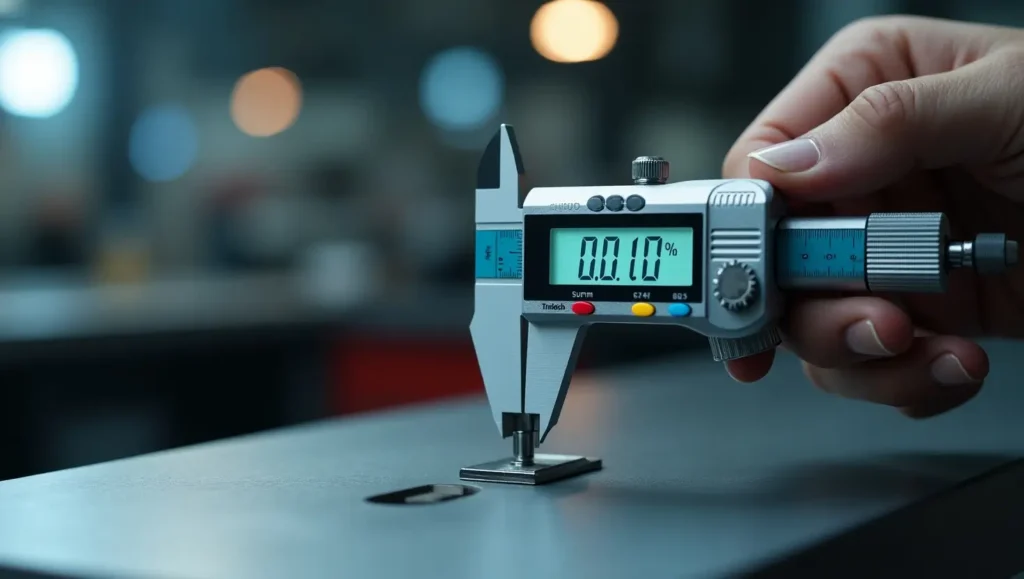

WELCOME to denzidesign.com Precision measurement is the backbone of industries like manufacturing, engineering, and scientific research. Whether you’re working in metal fabrication, automotive repair, or electronics, having accurate measurements is crucial for ensuring quality and consistency. This is where the digital micrometer becomes an invaluable tool. Unlike traditional analog micrometers, digital micrometers offer enhanced accuracy, ease of use, and quick readings—making them a go-to device for professionals and hobbyists alike.

In today’s fast-paced world, where precision engineering dictates the success of products and projects, relying on outdated measuring tools can lead to costly mistakes. The digital micrometer eliminates human error by providing precise digital readouts, often down to the micrometer level (0.001 mm or 0.00005 inches). Whether you’re a machinist working on high-precision parts, an automotive engineer measuring components, or a researcher in a laboratory, a digital micrometer ensures that your measurements are consistently accurate.

This guide explores everything you need to know about digital micrometers—how they work, their advantages over traditional micrometers, step-by-step usage instructions, and tips to ensure you get the most accurate readings. We’ll also cover different types of digital micrometers, maintenance tips, and key factors to consider when purchasing one. By the end of this article, you’ll have a clear understanding of why a digital micrometer is a must-have tool for precision measurement and how to use it effectively.

What is a digital micrometer?

A digital micrometer is a high-precision measuring tool designed to provide accurate readings of small dimensions, usually in the micrometer range. It works by using a calibrated screw mechanism and a digital display that instantly provides precise measurements. Digital micrometers are widely used in machining, engineering, and scientific fields where precision is critical.

Key Components of a Digital Micrometer:

- Frame: Provides structural support and stability.

- Anvil & Spindle: The measuring faces that come into contact with the object.

- Ratchet Stop: Ensures consistent pressure during measurement.

- Digital Display: Shows the measurement reading in real time.

- Locking Mechanism: Holds the spindle in place for accurate readings.

Unlike traditional micrometers, which rely on a vernier scale or dial reading, digital micrometers remove any ambiguity by displaying the measurement directly on an LCD screen, minimizing human error.

How to Use a Digital Micrometer

Using a digital micrometer correctly ensures precise and repeatable measurements. Follow these steps for accurate results:

- Check the calibration: Ensure that the micrometer is calibrated correctly before use. Most digital micrometers have a reset or zero function to set the baseline.

- Clean the Measuring Faces: Wipe the anvil and spindle with a lint-free cloth to remove dust or debris that could affect accuracy.

- Position the object: Place the object to be measured between the anvil and spindle.

- Rotate the Thimble or Ratchet Stop: Gently tighten the spindle against the object until a light but firm contact is made.

- Read the Measurement: The digital display will show the measurement in millimeters or inches.

- Lock the Spindle: If needed, use the locking mechanism to secure the reading.

Pro Tip: Always take multiple measurements for accuracy, especially when working with sensitive components.

Advantages of Digital Micrometers

Digital micrometers offer several benefits over traditional micrometers:

✅ Higher Accuracy: Digital micrometers provide precise readings with minimal human error. ✅ Ease of Use: No need to interpret scale markings—just read the digital display. ✅ Quick Measurements: Ideal for time-sensitive tasks requiring fast, reliable readings. ✅ Data Output: Many digital micrometers offer USB or Bluetooth connectivity for data logging. ✅ Unit Conversion: Easily switch between metric and imperial measurements.

Types of Digital Micrometers

There are various types of digital micrometers, each designed for specific measurement needs:

- Outside Micrometers: Measure external dimensions such as the thickness of an object.

- Inside Micrometers: Measure the internal diameter of holes or cylinders.

- Depth Micrometers: Measure the depth of holes, slots, and recesses.

- Screw Thread Micrometers: Specialized for measuring thread pitch diameters.

Choosing the right micrometer depends on the type of measurements required for your application.

Maintenance and Calibration

To ensure long-lasting accuracy and performance, follow these maintenance tips:

- Store Properly: Keep the micrometer in a protective case to prevent dust buildup.

- Avoid Excessive Force: Do not overtighten the spindle as it may damage the tool.

- Clean Regularly: Use a soft cloth and a small brush to clean dust and debris.

- Calibrate Periodically: Check calibration using a certified gauge block and reset if necessary.

- Battery Check: Replace batteries as needed to prevent display errors.

Regular maintenance helps extend the lifespan of your micrometer and ensures consistent accuracy.

Buying Guide: Choosing the Right Digital Micrometer

When selecting a digital micrometer, consider the following factors:

🔹 Accuracy & Resolution: Ensure it meets your precision requirements (e.g., 0.001 mm resolution). 🔹 Build Quality: Choose a micrometer made from durable materials like stainless steel. 🔹 Measurement Range: Select a micrometer suitable for the dimensions you need to measure. 🔹 Display & Features: Look for easy-to-read LCD screens, unit conversion, and data output options. 🔹 Brand Reputation: Trusted brands like Mitutoyo, Starrett, and Fowler provide reliable options.

Investing in a high-quality digital micrometer ensures precision and durability for years to come.

Conclusion

A digital micrometer is an essential tool for anyone who requires precise and accurate measurements in manufacturing, engineering, automotive, or laboratory settings. By eliminating the need for manual interpretation, digital micrometers provide faster, more reliable readings, making them a preferred choice over traditional analog micrometers.

Whether you’re a professional or a hobbyist, understanding how to use and maintain a digital micrometer ensures optimal performance and long-lasting accuracy. Investment in a high-quality microscope will not only improve efficiency but also reduce measurement errors, leading to better project outcomes.

Ready to upgrade your precision measurement tools? Explore top-rated digital micrometers today and experience unparalleled accuracy!